Waterproofing is a crucial part of construction that ensures buildings and structures are protected from water damage. One effective method for achieving this is through cementitious waterproofing. This article will delve into what cementitious waterproofing is, its benefits, its applications, and how to use it effectively.

What Is Cementitious Waterproofing and How Does It Work?

Cementitious waterproofing refers to a type of waterproofing system made from cement-based products. These materials are specially designed to create a barrier against water, making them ideal for various construction applications.

The primary ingredient, cement, is mixed with additives and other materials that enhance its waterproofing properties. Once applied, it forms a solid, water-resistant layer over surfaces such as concrete and masonry. This barrier prevents water infiltration, protecting the structure from potential damage caused by moisture.

Cementitious waterproofing works through a process known as capillary action. When water comes into contact with the cementitious layer, it creates a barrier that prevents water from moving through the surface. This means that even under high-pressure conditions, the water cannot penetrate the treated area.

Top Benefits of Cementitious Waterproofing Solutions for Your Building

Cementitious waterproofing offers numerous advantages for homeowners and builders alike. Here are some key benefits:

- Durability: Cementitious waterproofing is known for its strength and durability. Once cured, it can withstand harsh weather conditions and extreme temperatures, making it ideal for outdoor applications.

- Cost-Effective: Compared to other waterproofing methods, cementitious solutions are often more affordable. They provide long-lasting protection without breaking the bank.

- Ease of Application: Applying cementitious waterproofing is relatively simple. It can be brushed, sprayed, or rolled on, making it accessible for both professionals and DIY enthusiasts.

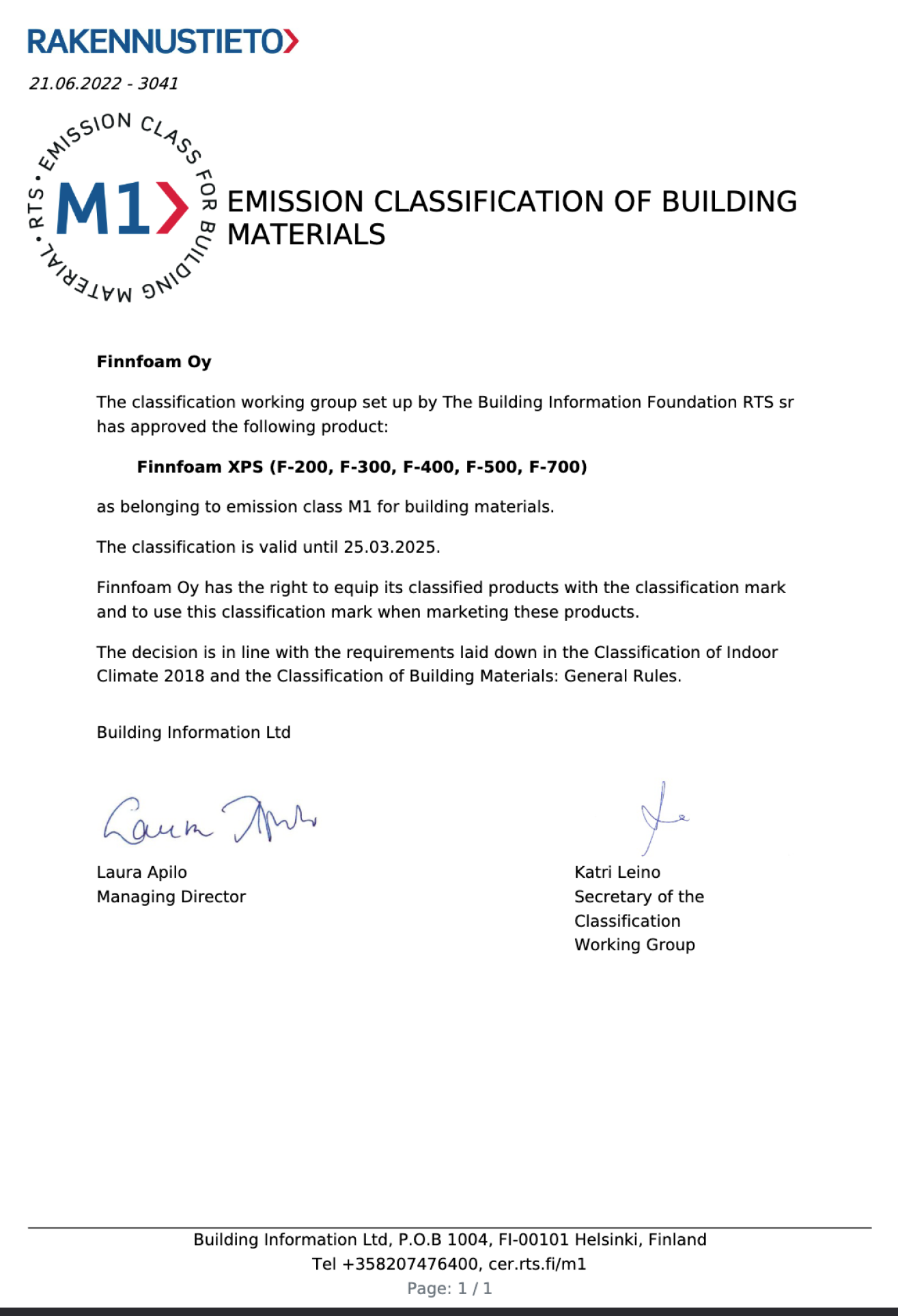

- Non-Toxic: Cementitious products are typically non-toxic and safe for use around children and pets. This makes them a great choice for residential properties.

- Versatility: Cementitious waterproofing can be used on various surfaces, including basements, foundations, terraces, and roofs. Its versatility makes it suitable for different construction projects.

- Moisture Control: By preventing water infiltration, cementitious waterproofing helps control moisture levels within the building. This reduces the risk of mold and mildew growth, improving indoor air quality.

Cement-Based Waterproofing: A Complete Guide for Homeowners

For homeowners looking to protect their properties, understanding cement-based waterproofing is essential. Here’s a step-by-step guide to help you navigate the process:

Step 1: Assess Your Needs

Before applying cementitious waterproofing, assess the areas that need protection. Look for signs of water damage, such as stains, mold, or peeling paint. Common areas that require waterproofing include:

- Basements: Often prone to water seepage, basements should be waterproofed to prevent flooding and mold growth.

- Foundations: Protecting the foundation is crucial for maintaining the overall stability of the building.

- Terraces and Balconies: These areas are exposed to the elements and need adequate waterproofing to prevent water damage.

Step 2: Choose the Right Product

Not all cementitious waterproofing products are the same. Research and choose a product that fits your specific needs. Look for features such as:

- Flexibility: Some products offer better flexibility, allowing them to expand and contract with temperature changes.

- Application Method: Consider whether you prefer a brush, spray, or roll-on application.

- Cure Time: Check the curing time of the product to ensure it aligns with your project timeline.

Step 3: Prepare the Surface

Proper surface preparation is key to the success of cementitious waterproofing. Follow these steps:

- Clean the Surface: Remove any dirt, debris, and loose material from the surface. A clean surface ensures better adhesion.

- Repair Cracks: Fill any cracks or holes in the surface with a suitable patching compound. This step helps create a smooth surface for application.

- Moisten the Surface: Lightly moisten the surface before applying the waterproofing product. This helps the material adhere better.

Step 4: Apply the Cementitious Waterproofing

Once the surface is prepared, it’s time to apply the waterproofing product. Here’s how to do it:

- Mix the Product: Follow the manufacturer’s instructions for mixing the cementitious waterproofing material. Ensure it’s a consistent and workable mixture.

- Start Application: Using a brush, roller, or spray, apply the waterproofing product evenly over the surface. Work in small sections to ensure even coverage.

- Apply Multiple Coats: Depending on the product and the area being treated, you may need to apply multiple coats. Allow each coat to dry before applying the next.

Step 5: Cure the Waterproofing

After application, curing is critical for the effectiveness of cementitious waterproofing. Allow the product to cure according to the manufacturer’s guidelines. Avoid exposing the area to water or heavy traffic during the curing period.

Cementitious Waterproofing Systems: Durable Protection for Concrete Structures

Cementitious waterproofing systems are essential for protecting concrete structures from water damage. Here’s a closer look at how these systems work:

How It Works

Cementitious waterproofing systems create a physical barrier that prevents water from penetrating the concrete. The combination of cement, water, and additives forms a strong bond that seals the surface.

When applied correctly, these systems resist hydrostatic pressure, making them suitable for below-grade applications like basements and foundations. They can also be used for above-grade applications, such as balconies and terraces, to provide comprehensive protection.

Types of Cementitious Waterproofing Systems

There are various types of cementitious waterproofing systems available. Here are a few popular options:

- Cementitious Coatings: These are thin, liquid-applied coatings that create a seamless waterproof barrier. They are ideal for surfaces that require flexibility and durability.

- Cementitious Membranes: These are thicker applications that provide a more robust waterproofing solution. They are often used in high-water areas and can handle more significant pressure.

- Cementitious Grouts: Used for filling voids and sealing joints, cementitious grouts can also serve as a waterproofing solution in areas with high moisture exposure.

How to Apply a Cementitious Waterproofing Coating for Optimal Results

Applying a cementitious waterproofing coating involves several straightforward steps. Here’s how to ensure optimal results:

- Gather Your Tools: You’ll need a mixer, brushes or rollers, a trowel, and protective gear such as gloves and goggles.

- Follow Mixing Instructions: Carefully follow the manufacturer’s instructions for mixing the waterproofing product. A well-mixed product ensures better performance.

- Apply Evenly: Use a brush or roller to apply the coating evenly over the prepared surface. Ensure complete coverage without any missed spots.

- Inspect for Defects: After application, inspect the surface for any defects. Fill in any gaps or areas that may require additional coating.

- Allow Proper Curing: Curing is essential for the coating to bond properly. Follow the manufacturer’s recommendations for curing time before exposing the surface to water or heavy use.

Key Applications of Cementitious Waterproofing in Construction

Cementitious waterproofing is versatile and can be applied in various construction scenarios. Here are some common applications:

- Basements: Preventing water seepage in basements is crucial for maintaining a dry and healthy living environment. Cementitious waterproofing effectively protects these areas from moisture.

- Foundations: The foundation is the backbone of any structure. Cementitious waterproofing helps safeguard it against water intrusion, ensuring stability and longevity.

- Rooftops: Flat or low-slope roofs are susceptible to water pooling. Using cementitious waterproofing can prevent leaks and protect the building’s interior.

- Terraces and Balconies: These outdoor spaces are exposed to weather elements. Cementitious waterproofing provides a protective layer that prevents water damage.

- Swimming Pools: Waterproofing swimming pools is essential to prevent leaks. Cementitious solutions create a water-tight seal that enhances durability.

The Best Cementitious Waterproofing Materials for Long-Lasting Results

Choosing the right cementitious waterproofing materials is crucial for effective results. Here are some top materials to consider:

- Polymer-Modified Cement: This type of cement includes polymers that enhance flexibility and adhesion. It’s ideal for areas subject to movement and stress.

- Hydrophobic Cement: Hydrophobic cement has water-repelling properties, making it an excellent choice for high-moisture environments.

- Fiber-Reinforced Cement: This material includes fibers that increase tensile strength and durability, making it suitable for high-traffic areas.

- Fast-Setting Cement: For projects requiring quick turnaround, fast-setting cementitious materials can be beneficial. They cure rapidly, allowing for quicker project completion.

Cementitious Membrane Waterproofing: Ensuring a Water-Tight Seal

Cementitious membrane waterproofing involves applying a thick layer of cement-based product to create a waterproof barrier. Here’s how it works:

Benefits of Cementitious Membrane Waterproofing

- Enhanced Durability: Cementitious membranes provide robust protection against water damage and are resistant to weathering.

- High-Pressure Resistance: These membranes can withstand significant hydrostatic pressure, making them ideal for below-grade applications.

- Flexibility: Many cementitious membranes are flexible, allowing them to expand and contract with temperature changes without cracking.